Natural essential (or volatile) oils are the volatile,

odoriferous oils obtained from plants. These are found in special cells, glands

or ducts located in different parts of a plant such as the leaves, barks,

roots, flowers and fruits and sometimes in just one or two parts. Essential oils are isolated from various plant parts such

as leaves, peel, bark, root, grass, wood, resin, berries, seeds, flowers,

rhizome and buds. These essential oils are extracted by either

cold pressing or distillation.

Distillation of aromatic herbs implies vaporising or

liberating the oils from the plant cells in presence of temperature and

moisture and then cooling the vapour mixture to separate out the oil from

water. It is the most popular method in use today for producing majority of

essential oils throughout the world. The apparatus used typically consist of a

still or a tank in which the plant material is kept, condenser where the vapour

mixture cools down and a receiver where the cooled down liquid is collected.

There are three types of distillation

Water / Hydro-distillation

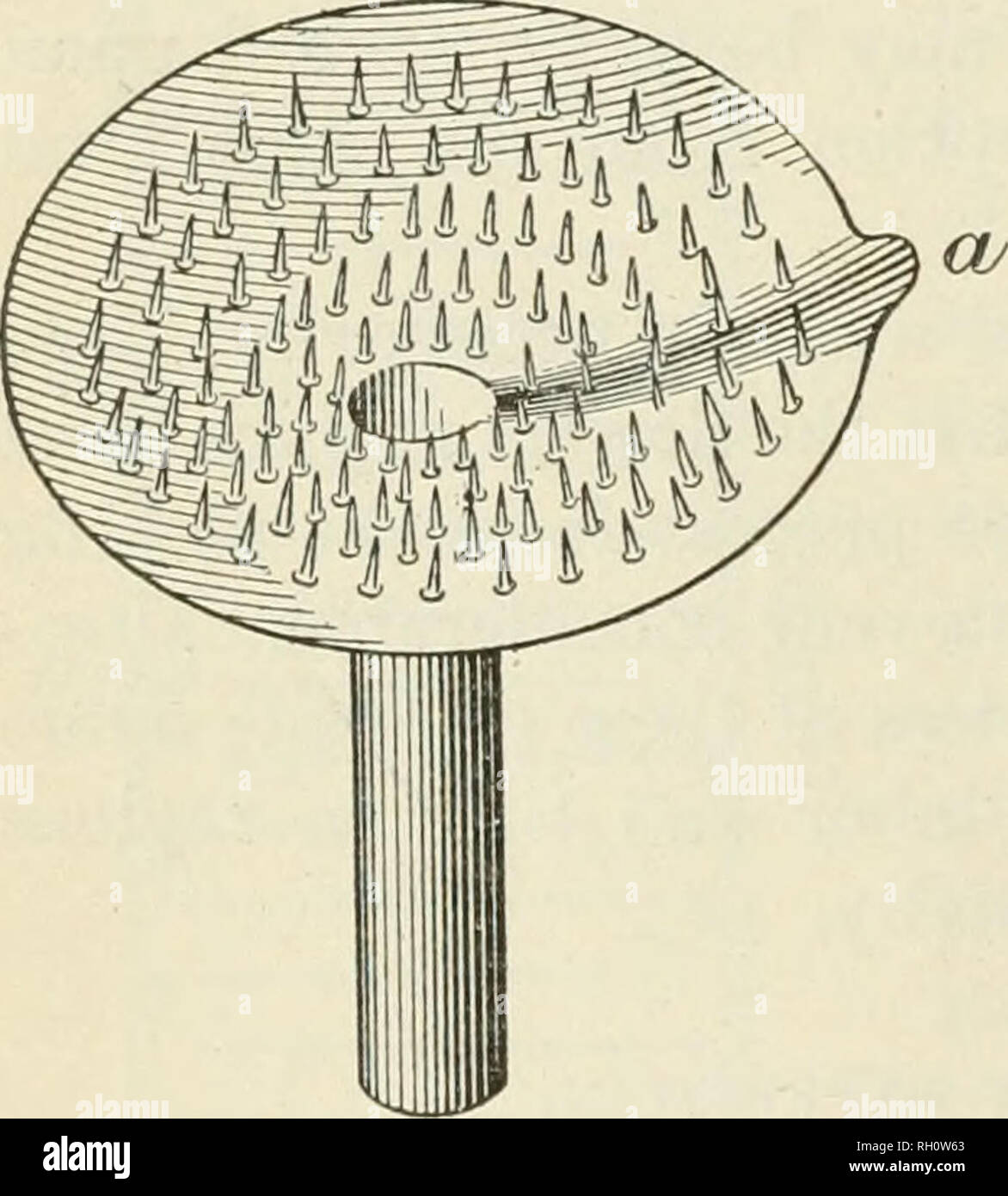

This process involves placing the

desired plant material in a still and then submerging it into water. The water

is then brought to boil. The steam

generated into the system penetrates the cell wall of the plant material and

the essential oil trapped is released and becomes volatile. The mixture of oil

and water vapours thus generated is cooled and two distinct layers of liquid

are formed. This is then collected and the oil is separated from the water. Hydro

distillation is used when plant material is dried and will not be damaged when

boiled. A special form of hydro distillation used in India is Deg-Bhapka. It is

used to make attars and fragrant water (hydrosols).

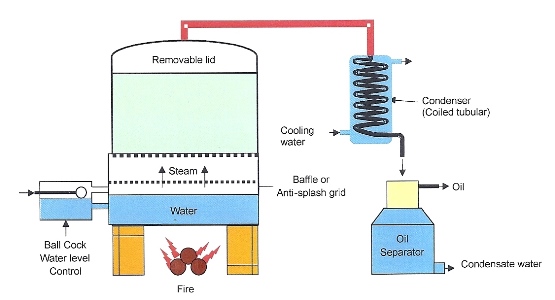

Water & Steam / Hydro-Steam distillation

In this process the plant

material is supported above the boiling water by a perforated grid or plate in

the tank. The water is boiled using a furnace or heating coils. The water

boils generating steam which passes through the plant material and releases

the essential oil in vapour form. This vapour mixture

is then passed through the condenser. The vapour cools down to form two distinct

layers of oil and water in the receiver. The oil is then separated. Typical example of this system is the Field Distillation Unit.

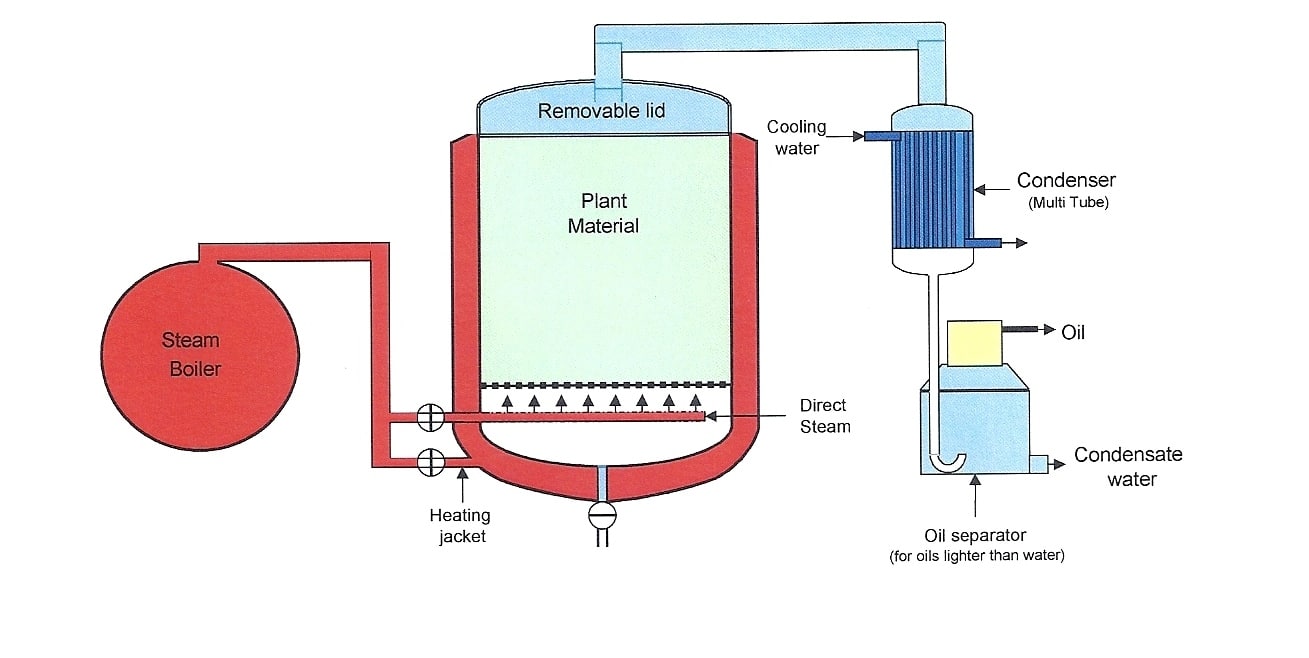

Steam / Direct distillation

In Steam Distillation steam is

directly applied to the plant material in the tank. The steam is generated

separately and introduced into the tank by a steam line. The steam passes through the plant material releasing

the volatile oil. This vapour mixture cools when it passes through the

condenser and gives two distinct layers of oil and water which is collected in

a receiver.

Some essential oil like lemon oil, bergamot oil, orange oil cannot be extracted without decomposition and are usually obtained by Expression or by other mechanical means. Most nuts and seed like groundnut oil, mustard oil etc are also extracted using this method. The oil is forced to come out of the material under high mechanical pressure which produces good quality oil. Since no heat is involved the oil extracted smells very close to the original plant. In case of citrus fruits like lemon, bergamot, orange etc. the rind is squeezed to obtain the essential oil they secrete.

Some essential oil like lemon oil, bergamot oil, orange oil cannot be extracted without decomposition and are usually obtained by Expression or by other mechanical means. Most nuts and seed like groundnut oil, mustard oil etc are also extracted using this method. The oil is forced to come out of the material under high mechanical pressure which produces good quality oil. Since no heat is involved the oil extracted smells very close to the original plant. In case of citrus fruits like lemon, bergamot, orange etc. the rind is squeezed to obtain the essential oil they secrete.